|

|

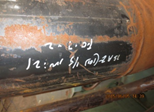

During patrol inspection, found that inside surface of FO transfer pipe rusty seriously in No3 FOT, Kindly advise which kind of surface treatment will be applied before installation.

Design Reply:

There is no treatment to be carried out for the both surface of transfer pipe, since before the F.O supplied to M/E ,G/E,AUX/BOILER, it has been through filters fitted at suction side for each pump, the F.O.2nd filter which capacity of 10u and F.O purifier. All of these can guarantee the quality of F.O which satisfy to the requirement of each F.O consumption equipment accordingly. Yours good understand and kindly accept will be highly appreciated.

Supervisor reply:

Noted your explanation, But keeping pipe in so bad condition is not acceptable. as you know, the period from pipe fabrication to pipe using is very long about 10 months, and also welding bead is not penetration weld, base on above description, kindly advise:

1, How much thickness of pipe will be corroded for so long time, kindly provide calculation sheet.

2, How to ensure quality of non-penetration welding bead in that serious corrosion condition with so long time.

Design reply:

With regard to the subject of comment as bellow,first of all for the thickness of the pipe corroded for so long time, please refer to the attached file of pipe thickness calculation.

And for the quality of non- penetration welding bead, the F.O transfer pipe will be test on board, if there any leakage occurred the disfigurement of welding position will be discovered easily. Yours kindly accept and good understand will be highly appreciated

问题提出:在巡查中发现3号FOT的FO输送管内表面生锈严重,请告知安装前要进行何种表面处理。

设计回复:

输油管道的两个表面无需处理,因为在输油管道供应给主机、G/E、AUX/锅炉之前,它已经通过每个泵的吸入侧安装的过滤器,即容量为10u的第二过滤器和输油管道净化器。所有这些都能保证离岸价的质量,满足相应的各离岸价消耗设备的要求。您的理解和接受将是高度赞赏。

监督回答:

我注意到了你的解释,但是把管子保持在这么糟糕的状态是不能接受的。如你所知,从管材制作到管材使用的周期很长,大约10个月,而且焊道也不是熔透焊,根据以上描述,请告知:

1、多长时间管道会腐蚀多少厚度,请提供计算书。

2、在长时间腐蚀严重的情况下,如何保证非熔透焊道的质量。

设计回复:

关于下面评论的主题,首先关于长时间腐蚀的管道的厚度,请参考附件的管道厚度计算文件。

而对于非熔透焊道的质量,船上会对F.O转移管进行检测,如果发生泄漏,很容易发现焊接部位的缺陷。如蒙接受并谅解,不胜感激。

这个问题是关于输油管内壁的锈蚀!我觉得管子处理有问题,不应该有锈蚀,但是设计确说没问题,大家评论下,好久没发问题了,发一个!

|

|