|

|

发表于 2019-12-26 12:46

|

显示全部楼层

发表于 2019-12-26 12:46

|

显示全部楼层

来自: 中国辽宁

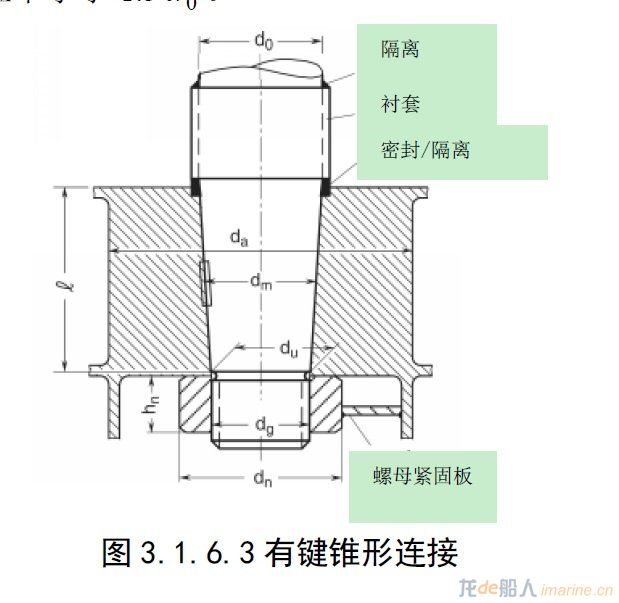

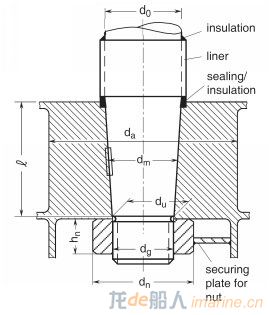

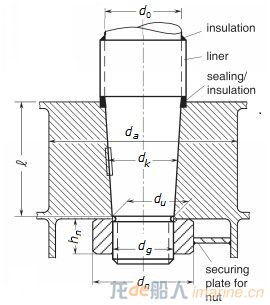

呵呵,稍等。舵杆拂配,CCS 钢规要求比较简单,语焉不详。DNVGL就详细多了,有指标具备可操作性。而且CCS连插图都懒得画,都是直接拷贝DNVGL的,明显侵犯知识产权了。第一张图片是CCS钢规PDF文件截屏,第二张文件是CCS钢规PDF文件图片复制,第三张图片是DNVGL规范图片复制。{:4_105:}CCS规范里大量存在这种插图,而且CCS英文规范也存在大段大段的原文抄袭。{:4_110:}可以说CCS中文规范就是抄的DNVGL英文版,而且还抄的丢三落四。

CCS钢规截屏

-->

-->

CCS钢规复制图片

-->

-->

DNVGL规范复制图片

-->

-->

CCS钢规page 2-219

3.1.6.3 有键锥形连接

锥形应精确适配。连接长度l 一般应不小于1.5 d0 。

DNVGL-RU-SHIP-PT3

6.4 Cone couplings with key

6.4.1 A rudder stock cone coupling connection without hydraulic arrangement for mounting and dismounting

shall not be applied for spade rudders.

6.4.2 An effective sealing shall be provided at each end of the cone coupling.

6.4.3 Tapered key-fitted (keyed) connections shall be designed to transmit rudder torque in all normal

operating conditions by means of friction in order to avoid mutual movements between rudder stock and hub.

The key shall be regarded as a securing device.

6.4.4 The contact area in way of the conical coupling shall be at least 70%, evenly distributed.

6.4.5 Tapering and coupling length

Cone couplings without hydraulic arrangements for mounting and dismounting the coupling shall have a taper

c on diameter of 1:8 - 1:12 where, see Figure 7:

The cone coupling shall be secured by a slugging nut. The nut shall be secured, e.g. by a securing plate.

The cone shapes shall fit exactly. The coupling length ℓ shall be, in general, not less than 1.5d0.

6.5 Cone couplings with special arrangements for mounting and dismounting the couplings

6.5.1 An effective sealing shall be provided at each end of the cone coupling.

6.5.2 Where the stock diameter exceeds 200 mm, the press fit is recommended to be effected by a hydraulic

pressure connection. In such cases the cone shall be more slender, c ≈1:12 to ≈1:20.

In case of hydraulic pressure connections the nut shall be effectively secured against the rudder stock or the

pintle, see Figure 8.

For the safe transmission of the torsional moment by the coupling between rudder stock and rudder body the

push-up pressure and the push-up length shall be determined according to [6.5.4] and [6.5.5], respectively.

6.5.3 The contact area in way of the conical coupling shall be at least 70%, evenly distributed.

类似的可以再参考一下,CCS 螺旋桨尾轴拂陪就一句话

钢规

11.4.5.4 在套合之前,桨毂与轴锥部的实际接触面积应不小于理论接触面积的70%。一般可着色进行

检查。不接触带不应环绕整个桨毂或延伸到整个桨毂全长。在最后拉入后,应用螺母把螺旋桨固定在轴上。

再找个DNVGL规范吧。

DNVGL-RU-SHIP-PT4

7.2.5 Keyless shrink fit connections shall be checked with regard to:

— circumferential orientation (marking) between the parts (not applicable to sleeve couplings)

— contact1) between male and female tapered members (not applicable for couplings certified as hub and

sleeve together and contact checked at the manufacturer). As a minimum there shall be a full contact

band at the big end

— shrinkage amount, verified by diametrical expansion or pull up length, whichever is approved

— draining and venting (by air).

1) For wet mounting, the contact may be improved by light grinding with a soft disc and emery paper in the

hub (not the shaft). A test pull up may also be used to improve the contact.

7.2.8 Propeller fitting

a) For flange mounted propellers, the bolt tightening shall be verified.

b) For cone mounted propellers with key, the following shall be verified:

— contact between propeller and shaft (e.g. by means of toolmaker’s blue) to be at least 70% and with

full contact band at the upper end, see also [7.2.5], footnote 1)

— push up force or pull up length, whichever is specified in the approval

— after final pull-up, the propeller shall be secured by a nut on the propeller shaft. The nut shall be

secured to the shaft with the approved locking arrangement. Alternatively, if approved, a split fitted

ring with locking arrangement may be used. The ring shall have a tight fit

— key fit in both shaft and hub.

c) For keyless cone mounted propellers, the following shall be verified:

— prior to final pull-up, the contact area 1) between the mating surfaces shall be not less than

70% of the theoretical contact area (100%). Non-contact bands (except oil grooves) extending

circumferentially around the hub or over the full length of the hub are not acceptable. At the big end

there shall be a full contact band of at least 20% of the taper length

— after final pull-up, the propeller shall be secured by a nut on the propeller shaft. The nut shall be

secured to the shaft with the approved locking arrangement. Alternatively, if approved, a split fitted

ring with locking arrangement may be used. The ring shall have a tight fit.

1) The contact may be improved by light grinding with a soft disc and emery paper in the hub (not the

shaft). A test pull up may also be used to improve the contact.

|

评分

-

查看全部评分

|