|

|

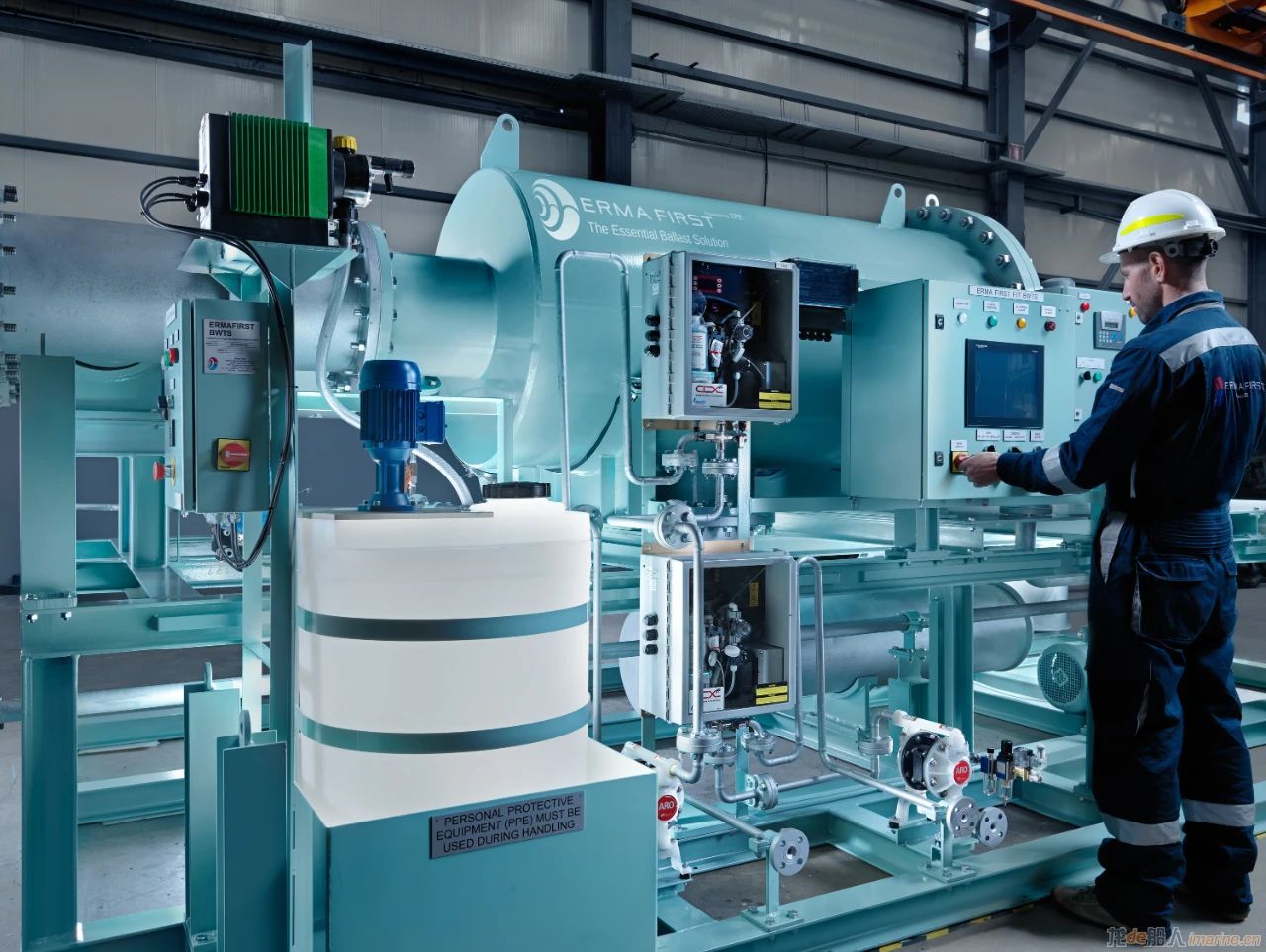

ERMA FIRST 是希腊一家致力于船用产品创新的制造商,自 2009 年以来一直在开发压载水处理系统 [BWTS]。公司在 BWTS 领域拥有全球知名的权威地位,已成功的在不同类型和尺寸的船舶中安装了我们的 BWTS 系统。

-->

-->

FIT 系列压载水处理系统是公司的畅销产品,已获得中国船级社 (CCS) 的修订型式认可和中国政府颁发的证书。该系统使用了先进的全流量电解氯化技术,可用于悬挂中国国旗的船舶,也是首个根据 IMO MEPC 300 (72) 决议在中国获得批准的同类系统。

-->

-->

该认可适用于 75-3000 的全系列型号,可选择三种过滤器类型:FILTERSAFE、FILTREX 和 HYDAC。

通过这种设计方式,压载水处理系统实现了高度灵活安装、使用简单、能耗低和完全合规的优势,可满足悬挂中国国旗船舶的船东和管理者多方面的要求。

多年来,ERMA FIRST 与中国造船厂合作开展了大量新造船和改造项目,在国际航运业也斩获了良好的口碑。ERMA FIRST中国团队不仅可以为客户提供强大的本地技术支持,还可以在本地和全球的范围内提供卓越的售后服务支持。

ERMA FIRST FIT 压载水处理系统占用空间小,可安装在沿海船舶和大型船舶之中。中国水域状况差异很大,既有水体清澈的近海水域,也有高度混浊的沿海地区。ERMA FIRST FIT 采用先进的全流量电解氯化技术,配备一个过滤系统,可以充分应对具有挑战性的水域条件,同时不会影响装卸货处理。

ERMA FIRST 在中国拥有 80 名服务工程师,在过去的 10 年中,一直都在提供压载水处理系统的安装和维护服务。公司的 FIT 系统已获得美国海岸警卫队的型式批准、IMO 最终批准和船级社型式认可。

ERMA FIRST 上海总经理Georgios Rentzeperis 表示:

“ERMA FIRST 拥有优秀的专业工程师队伍,与本地造船厂、船舶管理公司和船东开展了卓有成效的合作,因此可以为中国市场提供理想的服务。我们提供以客户为中心的个性化方法,同时也能让我们更好地服务于远东和欧洲的客户。持有中国船级社的型式认可和中国政府颁发的证书,对 ERMA FIRST 而言是一个莫大的荣誉。”

卓越解决方案

ERMA FIRST 认为,无论是从提高效率还是降低运营成本的方面考虑,全流程电解氯化方案都可以制造出最优质、最全面的产品。

ERMA FIRST FIT BWTS 包括一个过滤器部分,随后是进行全流量电解氯化。在消毒阶段会使用海水,通过过滤压载水的电解产生所需用量的消毒剂。ERMA FIRST FIT BWTS 系统还采用了特殊电极,可运行的环境范围广泛,为安全区域和危险区域安装提供灵活的解决方案。 水的盐度和透明度会严重影响 BWTS 充分发挥效果的能力。但全流量电解氯化系统配有过滤系统支持,因此可以低功耗快速处理大容量压载水。对于电解氯化系统和紫外线系统而言,浊度和低紫外线透射率会为系统带来完全不同的挑战。

该系统的目标是帮助全球船舶贸易实现合规性,已使用三种不同的 40μm过滤器对其进行独特的测试和认证。为了确认过滤器的性能,每个过滤器都会与专门设计的电解氯化单元结合使用。实验的生物功效结果符合并超过国际海事组织 [IMO] 和美国海岸警卫队 [USCG] 定义的排放标准。

改善运营成本表现BWTS 可以直接或间接的方式改善船舶的运营支出。BWTS 功耗是一项直接的运营成本。在具有挑战性的水域条件中,因 BWTS 流量限制而停靠在港口则是间接成本。

紫外线灯和石英套管老化是导致紫外线强度降低的一个重要例子,因为它会影响紫外线的剂量,只能采取流量减少/或者增加功率来达到效果。除了系统设计的限制(SDI)以外,操作模式的设计也要面对特定的操作模式挑战,需要提供一个可以有因数显示的压载水操作模式!

如需了解 ERMA FIRST 解决方案的更多信息,请访问:www.ermafirst.com

邮箱:sales@ermafirst.com

-->

-->

ERMA FIRST, an innovative Greek marine product manufacturer, has been developing ballast water treatment systems [BWTS] since 2009 As one of the most well respected BWTS specialists in world, they have successfully installed systems on a wide array of vessel types and sizes.

They currently hold an amended Type Approval from the China Classification Society (CCS) for its strong-selling FIT range of ballast water treatment systems and have been awarded Certificate under the Authority of the Government of the People’s Republic of China. The system, which uses advanced full-flow electro-chlorination technology, can be used on Chinese flagged vessels and is the first such system to receive approval in China under IMO Resolution MEPC 300 (72).

The approval is valid for the full range of models 75-3000 with the option of its three filter types: FILTERSAFE, FILTREX and HYDAC.

As a result, owners and managers of Chinese flagged ships have the option to install a highly flexible, simple to use, low energy and fully compliant ballast water treatment system.

ERMA FIRST has considerable experience working with Chinese shipyards on both newbuilds and retrofits, along with a proven track record across the international shipping industry as a whole. ERMA FIRST is proud to have a strong local technical presence through a Shanghai office and can provide excellent after-sales support both locally and globally.

The ERMA FIRST FIT ballast water treatment system has a small footprint and can be installed on coastal vessels as well as larger vessel types. Chinese waters vary significantly, ranging from clear offshore waters to highly turbid coastal areas. Using advanced full-flow electro-chlorination, backed up with a filtration system, means that ERMA FIRST FIT is able to cope with challenging waters without impacting cargo operations.

ERMA FIRST has 80 service engineers in China and has 10 years of experience installing and maintaining ballast water treatment systems. Its FIT system also holds USCG Type Approval, Final Approval by IMO and Class Type Approval.

Georgios Rentzeperis, ERMA FIRST Director in Shanghai, said:

"ERMA FIRST is ideally positioned to service the Chinese market with our expert engineers and considerable track record working in conjunction with regional shipyards, ship managers and owners. We offer a customer-centric and personal approach, which has served us well in both the Far East and Europe. Holding a Type Approval from the China Classification Society - and Certificate under the Authority of the Government of the People’s Republic of China - is a huge honour for ERMA FIRST."

A superior solution

ERMA FIRST passionately believes a full-flow electro-chlorination proposition is the best all-round offering, both in terms of effectiveness and reducing OPEX.

The ERMA FIRST FIT BWTS comprises of a filter stage, followed by full flow electro-chlorination. Sea water is used in the disinfection stage to generate the requisite amount of disinfectant through the electrolysis of the filtered ballast water. The ERMA FIRST FIT BWTS system also employs special Electrodes that allow a broad environmental envelope of operation, while offering flexible solutions for both safe area and hazardous zone installation. Water salinity and clarity can seriously affect the ability of a BWTS to work to its full potential. However, a full-flow electro-chlorination system - which is supported by filtration - can manage large volumes quickly with low power consumption. Turbidity and low ultraviolet transmissivity do not present the same challenges to an electro-chlorination system as they ordinarily would to a UV system.

The system is designed to deliver compliance for ships trading globally and hasbeen uniquely tested and certified with three different 40μm basket filters. Each filter’s performance has been proven in conjunction with the specially designed electro-chlorination cells. The achieved bio-efficacy meets and exceeds the dis-charge standards as defined by the International Maritime Organisation [IMO] and United States Coast Guard [USCG].

Focusing on OPEX

BWTS contributes to ship operational expenditure either directly or indirectly. BWTS power consumption is a direct OPEX. A stay in port due to BWTS flow restrictions in challenging water conditions would be regarded as an indirect cost.

Reduced UV intensity due to ageing UV lamps and quartz sleeves is an important example because it impacts UV dose, where flow reduction and/or power ramp up are resultant countermeasures. Operational modes designed to deal with specific operational challenges, in addition to system design limitations (SDL), provide a reasonable indication of factors that contribute to BWTS OPEX.

For more information on ERMA FIRST solutions please visit ermafirst.com

Email:sales@ermafirst.com

|

|